This test bed is designed to run accelerated degradation tests on rolling element bearings. The setup provides the capability for running tests under constant as well as time-varying operational conditions, specifically using various configurations of load and speed profiles. It also serves as a platform for implementing prototypes software modules for sensor-Driven Replacement software and Sensor-Driven Spare Part Inventory software.

This test bed is designed to run accelerated degradation tests on rolling element bearings. The setup provides the capability for running tests under constant as well as time-varying operational conditions, specifically using various configurations of load and speed profiles. It also serves as a platform for implementing prototypes software modules for sensor-Driven Replacement software and Sensor-Driven Spare Part Inventory software.

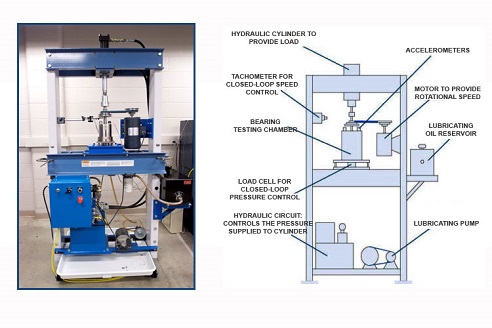

The test bed consists of a custom designed bearing testing chamber where test bearings are installed, loaded, and run to failure in an oil-bath. The upper race of the bearing is attached to the rotating shaft and the lower race is mounted on the base of the chamber. Two accelerometers are used to measure vibration of the chamber. A hydraulic unit and a cylinder provide axial loading (up to 2250 lbs/10 kN) capability while 1.5 HP DC motor (1750 rpm) along with a stacked pulley mechanism provides rotational motion at various speeds. Two feedback control loops are designed to maintain load and speed at designated target values with the aid of a tachometer for measuring rotational speed and a load cell placed under the test chamber to monitor the applied loads. Lubricating system provides lubricating oil to the test chamber while the tests are being performed. The system consists of an oil reservoir, a gear pump, and a filter. Oil is input at the top of the chamber and exists through a hose at the bottom. Data acquisition hardware from National instruments include, and NI-USB 6229 Board and an NI PCI-4462 board.

Multi-Component Diagnostics and Prognostics Research

A drivetrain diagnostics and prognostics test bed specifically designed to simulate industrial drivetrains with capability for performing accelerated degradation of gears and bearing, either simultaneously or individually (courtesy of Spectraquest).