The Typhoon 2.0 Environmental Chamber is used to perform Highly Accelerated Life Testing (HALT) on small electric and electronic products with capabilities to simulate thermal and vibrational stresses.

The Typhoon 2.0 Environmental Chamber is used to perform Highly Accelerated Life Testing (HALT) on small electric and electronic products with capabilities to simulate thermal and vibrational stresses.

The testing chamber features include a 24” x 24” vibration table with 5 vibration actuators for inducing repetitive-shock vibration during testing. It has one Accelerometer for Table Control Provided; and (3) additional accelerometer input channels available. Two 72” thermocouples provided; (1)for Product, (1)for Air, and (4) additional thermocouple input channels available, and (8) User Controllable Solid State Relays. For thermal cycling, the chamber consists of a cooling system that uses liquid Nitrogen injection and has a temperature range of +200ºC to -100 ºC.

Multi-Component Diagnostics and Prognostics Research

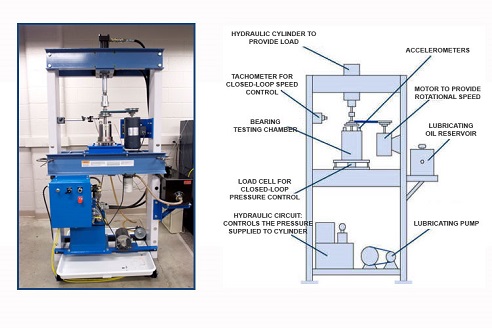

A drivetrain diagnostics and prognostics test bed specifically designed to simulate industrial drivetrains with capability for performing accelerated degradation of gears and bearing, either simultaneously or individually (courtesy of Spectraquest).